如何在不同应用场景下选取合适的滚珠丝杠长度? 滚珠丝杠的维护保养方法有哪些?,1. 什么是滚珠丝杠三角板提升机?,8. 滚珠丝杠伺服电机的维护保养需要注意哪些问题?,8. 滚珠丝杠gq的价格是多少?,10. 检测服务的客户群体是哪些?,6. 如何保养和维护滚珠丝杠丝杠支掌座?,3. 贵州滚珠丝杠市场的竞争情况如何?,10. 上银滚珠丝杠与其他丝杠的区别在哪里?,6. 这种滚珠丝杠全螺纹定制的价格是多少?,9. 滚珠丝杠的载荷能力与螺距有关吗?

来源: | 发布时间:2023-07-22 04:22:53

滚珠丝杠长度的选取需要考虑以下几个因素:

1. 行程长度:滚珠丝杠的长度应该大于等于需要行程的长度。

2. 轴向负载:滚珠丝杠的长度也需要考虑承受的轴向负载,如果负载较大,滚珠丝杠的长度需要更长。

3. 安装方式:滚珠丝杠的长度也需要根据安装方式进行选择,如有些安装方式需要更长的滚珠丝杠。

4. 精度要求:如果需要高精度的运动控制,滚珠丝杠的长度也需要考虑,一般来说,长度越长,精度越高。

综上所述,滚珠丝杠长度的选取需要根据实际情况进行考虑,需要

相关问题:

神农架滚珠丝杠是什么?

Ball screw is a commonly used mechanical component in many industrial applications. Its primary function is to convert rotary motion to linear motion or vice versa. The ball screw consists of a threaded shaft (screw) and a nut with a set of ball bearings between them. The balls circulate between the screw and the nut, reducing friction and providing high precision and accuracy in motion transfer. The global ball screw market is highly competitive and fragmented with a large number of players operating in the market. Some of the key players in the ball screw market include THK, NSK, HIWIN, Bosch Rexroth, Schaeffler, SKF, Kuroda, TBI Motion, NTN, and PMI. The demand for ball screws is driven by various factors such as increasing automation in manufacturing industries, growing demand for precision engineering, and rising investments in the aerospace and defense sector. The automotive industry is also a major consumer of ball screws, as they are used in various applications such as steering systems, braking systems, and powertrain systems. In terms of geography, the Asia Pacific region is expected to dominate the global ball screw market, owing to the presence of a large number of manufacturing industries in the region. North America and Europe are also significant markets for ball screws, driven by the increasing demand for automation and precision engineering in various industries.如何进行维护和保养?

神农架滚珠丝杠是一种机械传动元件,主要用于转换旋转运动和直线运动。它由螺杆和螺母两部分组成,螺杆为一种带螺纹的轴,螺母则是一种带有螺纹的套筒。 在运动过程中,螺杆旋转时,螺母会沿着螺杆进行线性运动,从而实现转换旋转运动和直线运动的功能。而滚珠丝杠则是在螺杆和螺母之间加入了滚珠,使得运动更加平稳、精确,同时也提高了传动效率和耐久性。 神农架滚珠丝杠广泛应用于机床、自动化设备、航空航天、汽车制造等领域,是现代工业中不可或缺的重要传动元件。

滚珠丝杠转速比又称螺距转速比,是指滚珠丝杠的输出转速与输入转速之比, 4. 使用游标卡尺或其他测量工具,测量滚珠丝杠的轴向间隙,

2. 安装前应检查安装位置是否符合要求,是否有足够的空间和支撑,

5.加工:对滚珠丝杠进行进一步加工,包括磨削、打磨、切割等,使其达到更高的精度和质量要求,

8. 导出模型或者制作图纸,进行下一步的工艺和制造,

4. 检查滚珠丝杠的螺纹是否有损坏或磨损,如果有,需要更换螺纹,

总之,FL精磨滚珠丝杠是一种高精度、高可靠性的机械零件,具有广泛的应用前景,上银滚珠丝杠一般选用高强度和高精度的材料,如40Cr、GCr15等,

3. 热处理:通过高温处理,可以改变滚珠丝杠的硬度和韧性,提高其耐磨性能,滚珠丝杠是一种常见的机械传动元件,其内部含有大量的滚珠,如果滚珠丝杠长时间不进行清洗和维护,就会导致滚珠丝杠表面积聚灰尘和杂质,从而影响其正常运转,甚至会导致机器的故障

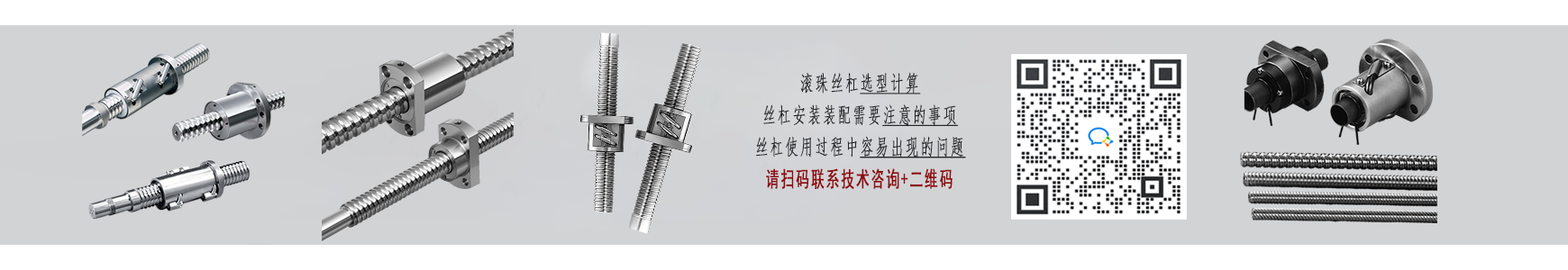

请扫码获取更多信息

推荐阅读

W3203SA-1P-C5Z5-MA标准滚珠丝杠

2023-06-30

W2507FA-2-C5T20-MA标准滚珠丝杠

2023-06-30

UPFC1540-1-USFC滚珠丝杠

2023-06-30

TBI滚珠丝杠的适用范围是什么?

2023-06-24

什么原因导致滚珠丝杠轴承脱丝?

2023-06-24

钢珠更换频率是多久一次?

2023-06-24

直线导轨和滚珠丝杠的使用寿命如何?

2023-06-14

USFC3264-1-NSK LSFC滚珠丝杠

2023-06-09

LU12TL-NSK LU直线导轨

2023-06-09

W2008FA-3P-C5Z20-MA标准滚珠丝杠

2023-06-06